PHA: A Key Player in Bioplastics Innovation

The latest research underscores the critical role of Polyhydroxyalkanoate (PHA) in addressing global plastic pollution. Derived from renewable sources, PHA is biodegradable and offers a viable alternative to traditional plastics. Unlike conventional materials, it breaks down in various environments, reducing long-term waste accumulation.

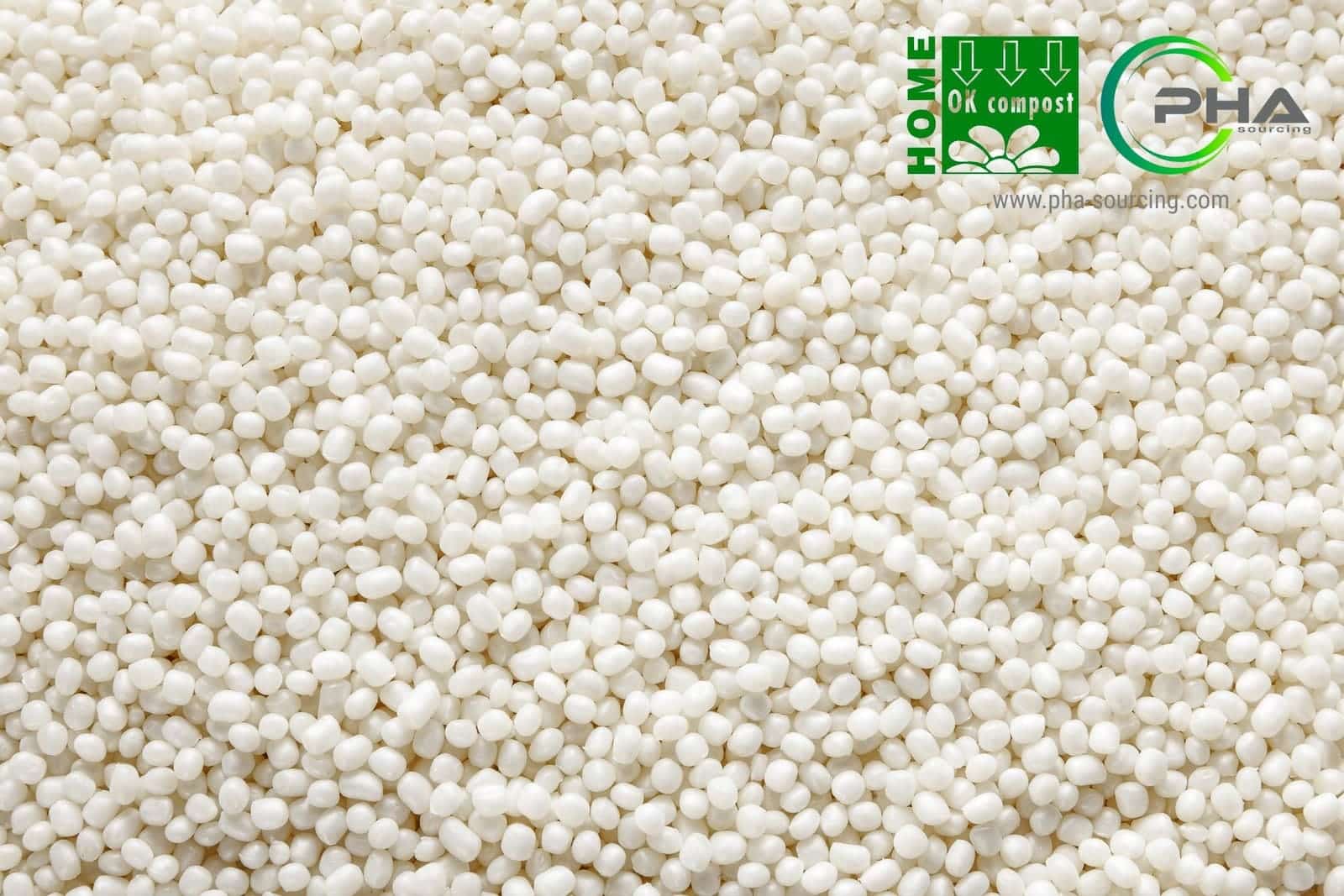

One of the key findings is PHA’s compatibility with industrial production processes, making it an attractive material for manufacturers seeking sustainable solutions. Its flexibility allows it to replace fossil-based plastics in applications ranging from packaging to medical devices, showcasing its adaptability across industries.

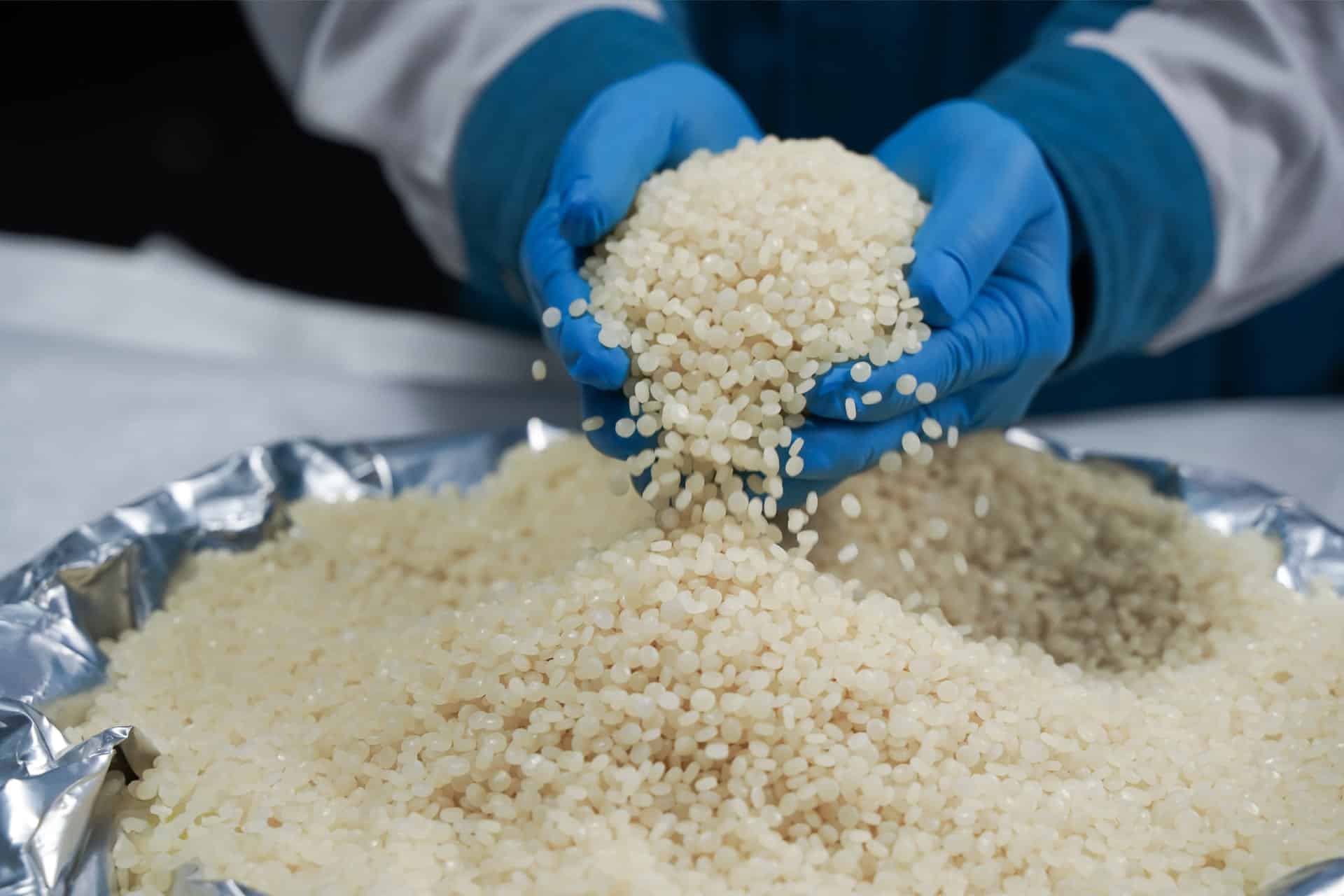

The study also highlights how advancements in microbial fermentation techniques have improved the cost-effectiveness and scalability of PHA production, further solidifying its position as a leading material in the bioplastics sector.

Composting: A Sustainable End-of-Life Solution

The biodegradability of PHA is one of its most significant advantages, particularly in the context of waste management. The study reveals that PHA can decompose fully in environments such as soil, marine settings, and industrial composting facilities, making it an ideal material for a circular economy.

When integrated into various composting systems, PHA ensures a sustainable end-of-life solution that aligns with global efforts to reduce landfill waste. This feature is especially relevant as regulatory frameworks push for materials that support a zero-waste approach.

Furthermore, PHA’s ability to biodegrade without leaving microplastic residues is a game-changer in combating environmental pollution. This property differentiates it from many other so-called “biodegradable” plastics, which often require highly specific conditions to break down.

Expanding Applications of Bioplastics

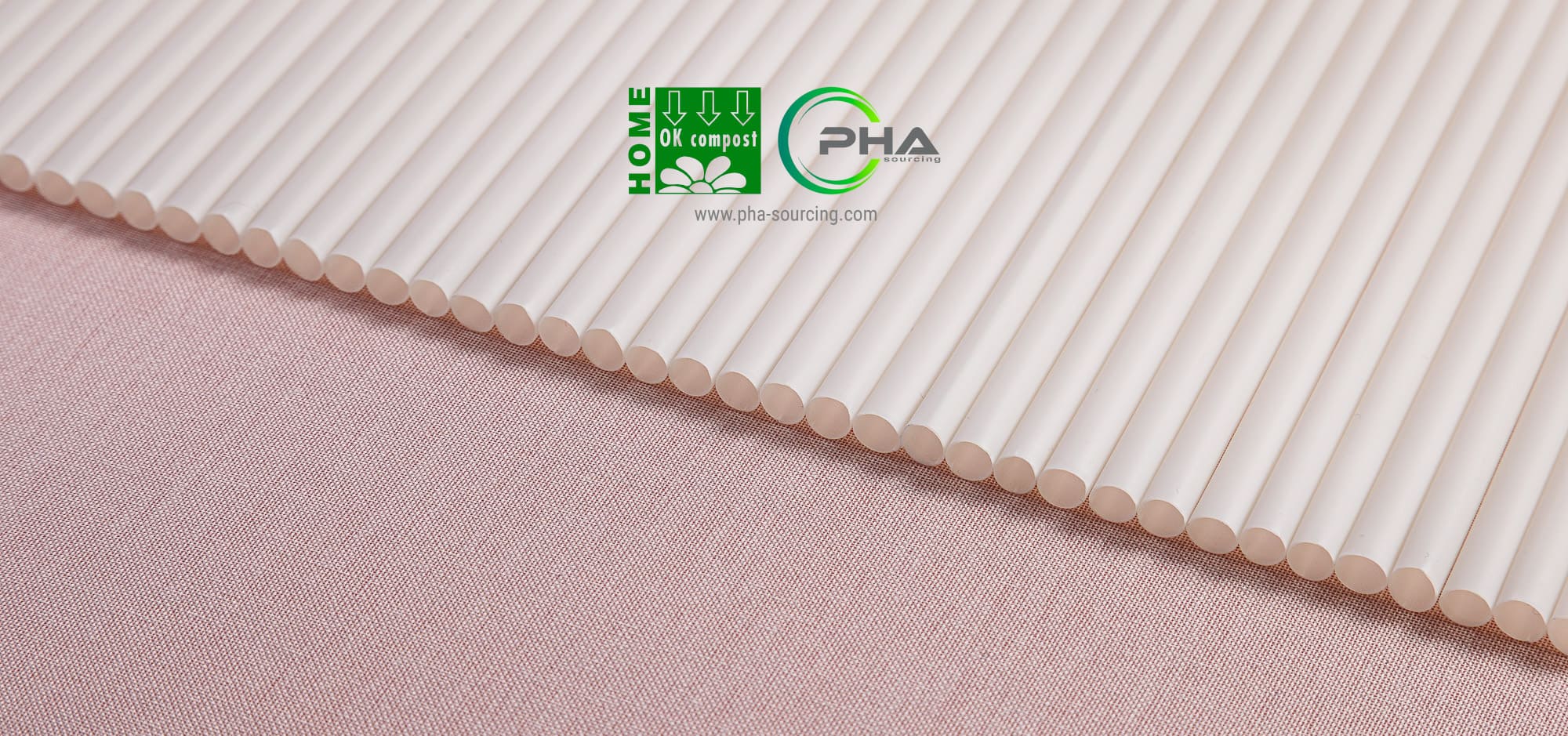

One of the study’s key takeaways is the wide range of applications for bioplastics, with PHA emerging as a versatile material for multiple sectors. In packaging, PHA is already being used for compostable solutions like single-use cups and food containers, offering businesses a way to meet sustainability goals while maintaining functionality.

In agriculture, PHA is making inroads as a biodegradable alternative for mulch films and planting materials. Its non-toxic nature ensures that it doesn’t harm soil health, making it a sustainable choice for farming applications. Additionally, industries like healthcare and automotive are exploring PHA for products such as medical-grade equipment and lightweight car parts.

The versatility of PHA is further enhanced by ongoing innovations in its formulation, allowing manufacturers to tailor its properties for specific needs. This adaptability not only expands its potential use cases but also drives its adoption in markets seeking durable yet eco-friendly materials.