PHAs have become famous for their use as biodegradable and bio compostable plastics. This trajectory aims to replace their petrochemical cousins alongside the famous polylactic acid (PLA). Their wide variability, from rigid thermoplastics to flexible elastomers, reflects their adaptability to many uses. Advances in research are constantly extending their applications beyond their initial function in bioplastics: here’s an overview.

Overview of the bioplastics market

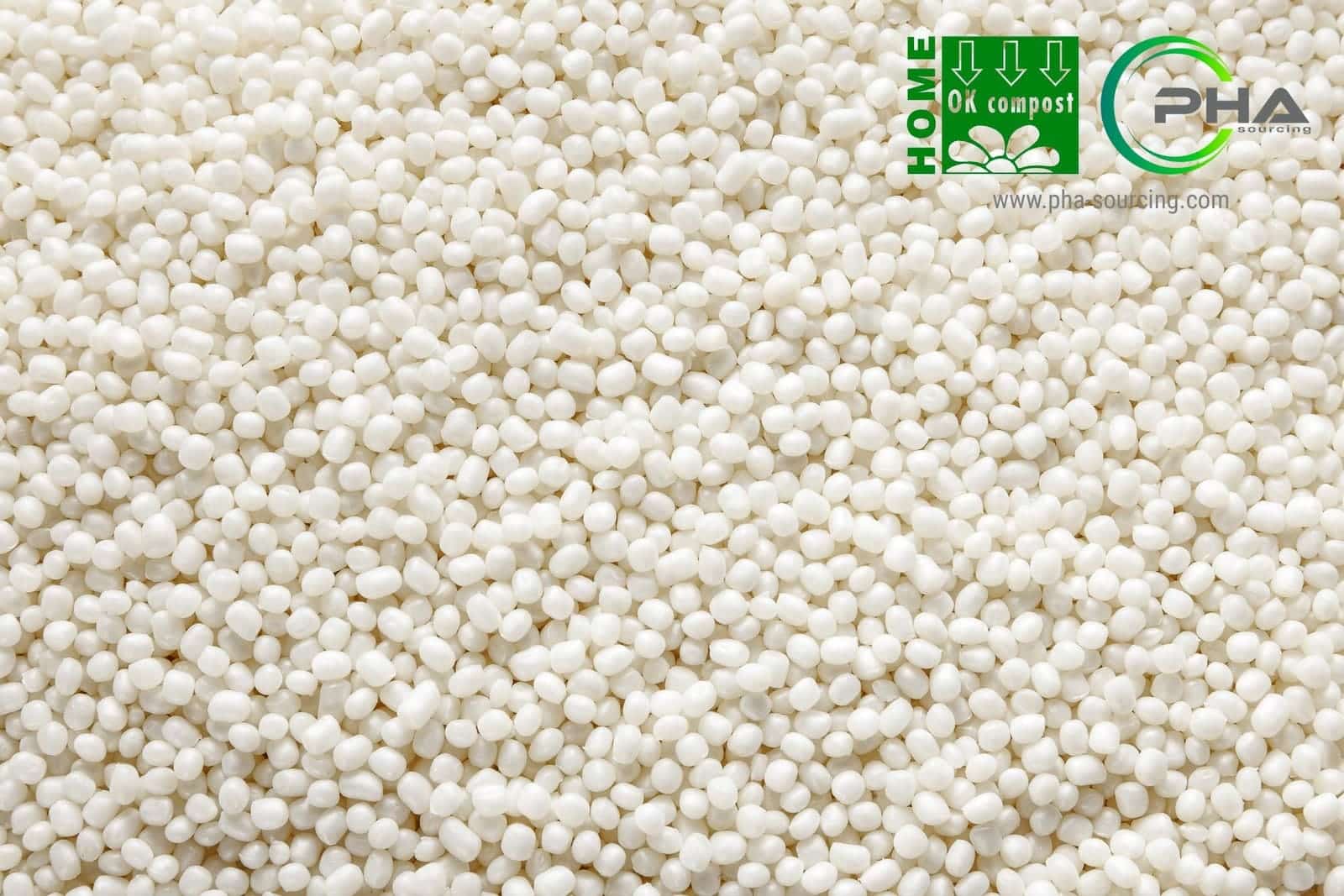

The rise of PHA tablets

The bioplastics market is growing rapidly, supported by strict environmental regulations and increased awareness of sustainability. According to the European Bioplastics Association, global bioplastics production could reach 2.87 million tonnes by 2026! PHAs are therefore among the most promising materials in this context of ecological transition.

Developments in PHA production

In terms of production, PHA biopolymers are characterised by their diversity. They can be produced by 92 genera of bacteria under aerobic or anaerobic conditions, and more than 160 PHA monomers have been identified. These polymers are classified as short-chain or medium-chain PHAs, depending on the number of carbon atoms they contain.

Fermentation and progress of PHA

To guarantee consistent quality, it is essential to standardise the fermentation processes and choose the right bacterial strains. The use of well-defined carbon sources, such as glucose, or renewable raw materials, such as food waste, contributes to the economic and ecological viability of production.

PHA tablets: techniques used and key points

Scientific quality and coherence

Specific strategies are used to maintain consistent quality between batches:

- The use of robust bacterial strains, limiting variations in polymer structure.

- Well-defined fermentation conditions and the use of homogeneous carbon sources such as glucose.

- Controlling cellular metabolism to exploit economical and sustainable raw materials, such as food waste hydrolysates.

Stages and constraints associated with PHA tablets

Standardisation of fermentation processes is essential for optimum quality control. Using a clear carbon source (such as glucose) improves the reliability of the results. Continuous monitoring during microbial culture is also essential. Finally, cellular metabolic constraints are crucial for exploiting inexpensive and environmentally-friendly raw materials.

Choice of raw materials and other techniques for bioplastics

Unconventional raw materials, such as food waste hydrolysates, have been used successfully. This has been made possible by the genetic stabilisation of key enzymes in the PHA pathway. Today, these enzymes are integrated into essential genes.

Other techniques include metabolic engineering to block pathways that modify the composition of PHA monomers. For example, modifying the PHA synthase enzyme (PhaC) so that it targets specific monomers is another promising strategy!

The role of PHAs in the transition to sustainable solutions

Bioplastics include plastics derived from plants, agricultural byproducts and renewable biomass. They also include materials that degrade naturally under the action of microorganisms. In short, unlike fossil plastics derived from oil, bioplastics use renewable resources and are ecologically favourable.

Producing PHA by fermentation uses less energy than manufacturing fossil plastics. Petrochemical processes require energy-intensive extraction and emit greenhouse gases. Fortunately, PHA’s carbon emissions are lower, at 1.5 to 3 kg CO2 equivalent per kilogram produced. Reducing energy and limiting the chemicals used in downstream processing is therefore crucial.

PHA tablets: prospects for bioplastics

Production costs still too high

PHA represents a challenge, as it remains more expensive than petroleum polymers. However, the development of PHA products – and in various industrial sectors – could help to reduce these costs. Ultimately, economies of scale and technological advances could make PHAs more competitive with traditional plastics. The best is yet to come…

New production methods

Traditional methods of producing PHA involve high costs, but researchers are developing innovative alternatives:

- Use of organic waste: transforming bio waste into PHA reduces costs and makes the most of unused resources.

- Optimising bacterial strains: genomic editing can improve production yields.

- Continuous fermentation: this technique reduces cycle times and energy costs.

These advances make PHAs more competitive than traditional plastics. Collaborative initiatives, in particular those funded by Horizon Europe, are accelerating their integration into the market. Yes, governments and institutions are encouraging these initiatives.

Making PHAs cost-competitive remains a complex challenge, and requires a number of obstacles to be overcome. Of course, PHAs still have to compete with traditional plastics, but what progress is not without its constraints?

PHA pellets have evolved into versatile biopolymers, transcending their origins as simple bioplastics. Research and development efforts are key to improving the commercial viability of PHAs as a sustainable alternative to conventional plastics. As a supplier of PHA pellets, our company can help you with your projects: contact our teams!