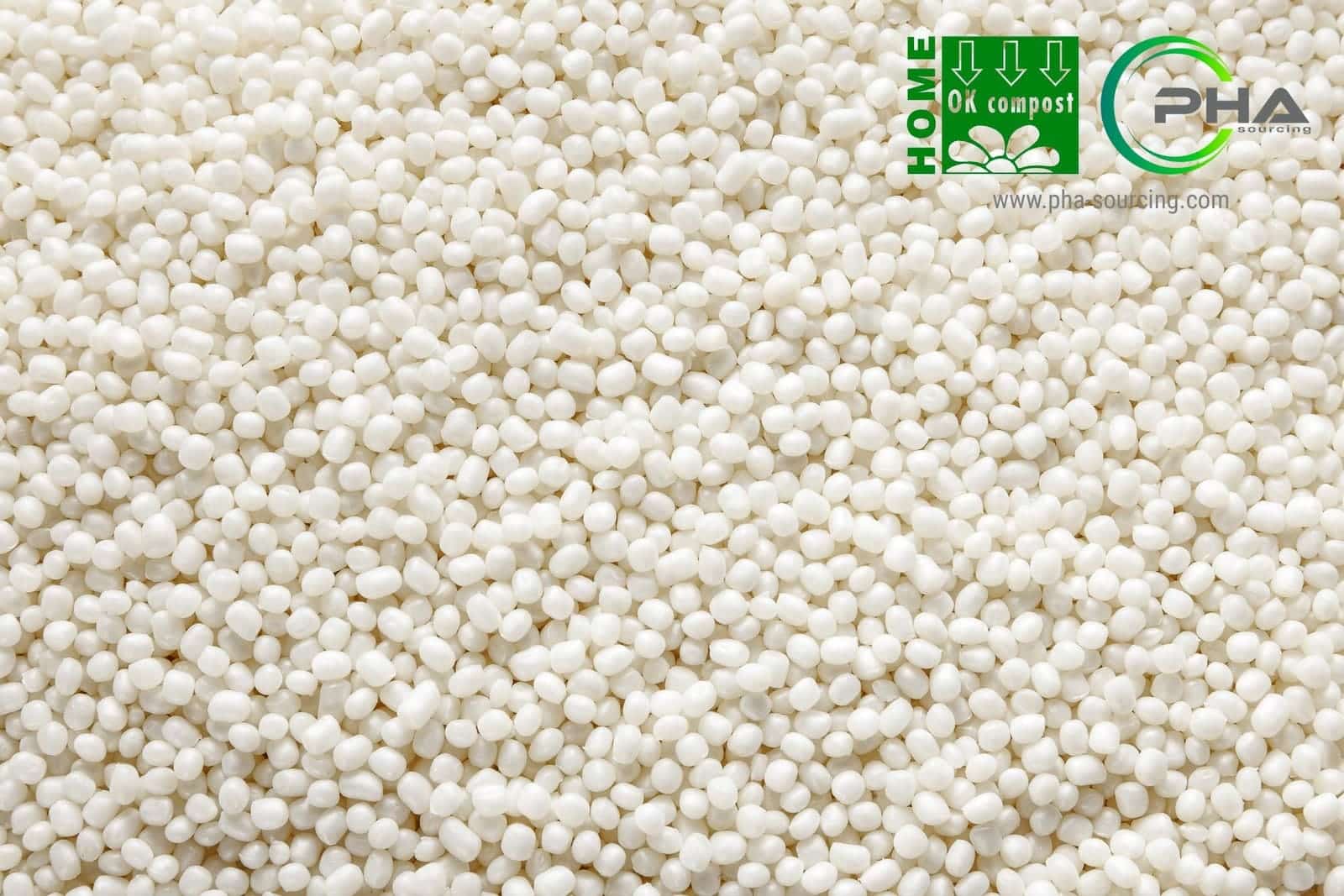

In a groundbreaking development presented at the Greener Manufacturing Conference, Fortum Recycling & Waste unveiled Inga – what they claim to be the world’s first biodegradable plastic made entirely from CO₂ emissions. This innovative PHA material represents a significant leap forward in sustainable plastic production.

A New Era for Plastic Manufacturing

“It is time to rethink plastic production and move away from fossil feedstock,” stated Tony Rehn, head of the Inga development team. This CO₂-derived PHA offers mechanical properties that can be precisely tuned to meet specific application requirements, while being fully recyclable and biodegradable across all tested environments:

- Marine and freshwater

- Soil and home composting

- Landfill conditions

- Anaerobic digestion

- Industrial composting

Unlike conventional plastics, Inga produces no microplastics and maintains quality comparable to virgin plastics, making it a true game-changer in the plastics industry.

Looking for truly sustainable plastics? Fortum’s CO₂-derived Inga PHA matches virgin plastic quality while being fully biodegradable. Explore how PHA Sourcing can help you access innovative materials like Inga for your products.

Versatile Applications for Sustainable Solutions

Inga’s unique properties make it suitable for diverse applications:

- Electronic appliances (thanks to its inherent rigidity)

- Toys and children’s products (combining durability and safety)

- Cosmetics packaging (meeting hygiene and aesthetic requirements)

- Food packaging (with excellent barrier properties including low water/oxygen transmission and high grease resistance)

Technical Advantages and Market Potential

The name “Inga” (meaning “nothing” in Swedish) reflects its circular economy principle – requiring no new resources for production. Key benefits include:

- Comparable quality to virgin plastics

- Complete biodegradability without microplastic formation

- Tunable mechanical properties for various applications

- Superior barrier properties for food safety

Fortum successfully produced the first Inga samples in October 2024, marking a major milestone in their journey toward commercialization. “Our goal is to have the first Inga plastic products on the market within this decade,” Rehn announced.

Addressing Global Plastic Challenges

With global plastic demand expected to triple by 2050, innovative solutions like Inga are crucial. While Fortum continues producing Circo plastic recyclate from post-consumer waste since 2016, Inga represents a complementary approach to creating truly sustainable plastics.

“We want to promote the circulation of materials comprehensively,” Rehn emphasized. “Inga will establish a new category of responsible plastics, though we recognize that mechanical recycling and other bio-based solutions remain essential components of a sustainable plastic economy.”

PHA Sourcing: Your Partner for Innovative Materials

As the plastics industry evolves with breakthroughs like Inga, PHA Sourcing remains committed to connecting businesses with the most advanced sustainable materials. Our expertise in various PHA types and applications helps companies stay at the forefront of this materials revolution, offering access to high-quality, environmentally responsible plastic solutions that meet both performance and sustainability requirements.