Polyhydroxyalkanoate (PHA) production is moving from niche biotechnology to an industrial priority, pushed by plastic pollution pressure, biodegradability requirements, and circular economy commitments. For entrepreneurs, converters, and investors, the main question is no longer “why PHA”, but “how to build a plant that performs economically”. This overview explains what typically shapes a PHA production plant setup cost, from feedstock handling and fermentation through downstream recovery, utilities, and compliance. It also highlights the key OpEx drivers and profitability levers that can make a PHA project bankable across packaging, agriculture, medical, and consumer goods demand.

CapEx roadmap: what drives a PHA production plant setup cost

Site, buildings, and compliance infrastructure

A PHA facility is not only a factory, it is a controlled biotech environment. Capital needs typically start with land acquisition or leasing in industrial or biotech zones, followed by site preparation and foundations designed for large fermentation vessels. Beyond warehouses and offices, projects often include laboratories for quality and microbiology, controlled fermentation halls, downstream processing areas designed for solvent-rated operations when required, and dedicated zones for receiving feedstock and dispatching pellets.

Environmental and biosafety CapEx can be material: effluent treatment for fermentation wastewater, air and odor control, solvent emission mitigation and recovery, and biosecurity systems such as access control and decontamination protocols. These investments are often decisive for permits, operational continuity, and customer acceptance in regulated applications such as food contact packaging and medical uses.

Core process equipment: fermentation and downstream recovery

The dominant investment line is usually the bioprocess itself. Polyhydroxyalkanoate (PHA) production relies on bacterial fermentation using feedstocks that can range from sugars and oils to agricultural residues or industrial off-gases. Typical CapEx elements include large bioreactors (often in the 10,000 to 100,000+ liter range), seed fermenters, sterile aeration and filtration, agitation and mixing, temperature control, online monitoring (pH, dissolved oxygen), and automated feeding. Clean-in-place (CIP) and sterilize-in-place (SIP) systems are standard to reduce contamination risk and batch failure.

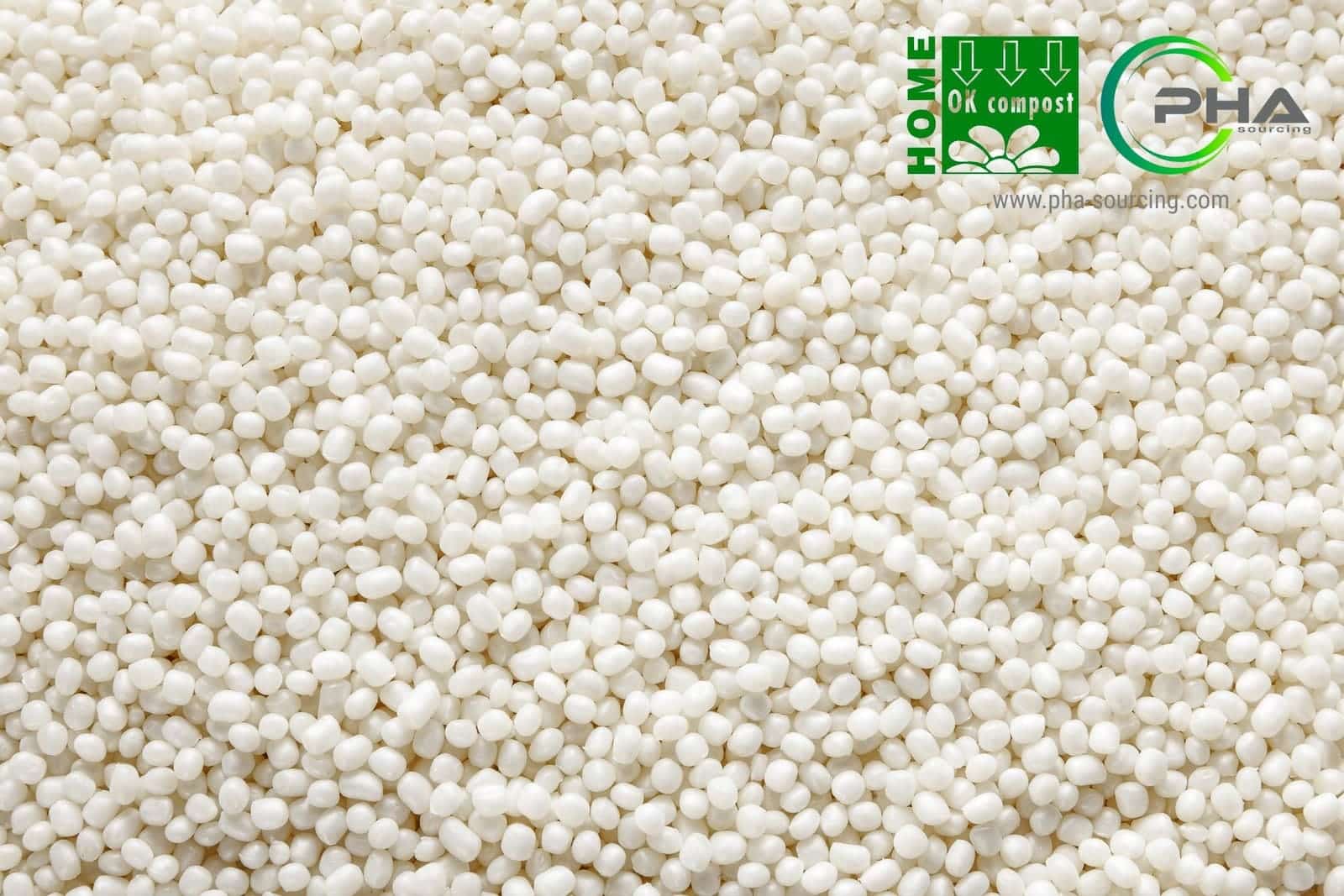

Downstream processing adds another major layer: harvesting (centrifugation or filtration), cell disruption and extraction, polymer precipitation and washing, drying, and pelletizing or compounding. The chosen recovery pathway (solvent extraction, enzymatic digestion, or mechanical disruption) can strongly influence both the equipment list and ongoing environmental controls. For polymer characterization and release specifications, plants commonly budget for analytical capability such as HPLC/GC, thermal analysis, mechanical testing, and microbiology verification of strains.

OpEx and profitability: how projects win after commissioning

Main operating cost drivers to model early

In many business cases, feedstock is the single largest operating cost and can represent roughly 40-60% of production cost depending on the chosen source. Utilities (power, steam, water, cooling) are typically the next major component, especially because fermentation requires continuous control and downstream recovery may be energy intensive. Additional OpEx lines include skilled labor for bioprocess operations, maintenance, nutrients and consumables, certification and quality testing, wastewater treatment, and solvent recovery where applicable.

Because fermentation is sensitive to contamination, the financial model should account for the cost of prevention (sterile systems, training, validation) and the impact of batch failures. A high-performing plant is not defined only by nameplate capacity, but by stable yields, consistent polymer properties, and strong utilization without prolonged downtime.

Profit levers: scale, feedstock strategy, and grade positioning

Profitability often depends on matching technology choices to the target market. Pilot scale projects (roughly 50-200 tons per year) can validate strains and applications, but commercial competitiveness typically improves as plants move to thousands of tons per year with higher automation and optimized fermentation trains. Feedstock strategy also shapes margins: sugar-based inputs can simplify fermentation and improve consistency, while agricultural waste can reduce input cost but requires pretreatment and tighter quality management.

Product strategy matters as much as process performance. Short-chain-length PHA grades (such as PHB and PHBV) can fit rigid packaging and injection molding, while medium-chain-length PHA can support flexible applications and premium pricing. Many ventures also explore additional revenue potential from contract manufacturing, co-products from biomass, or programs linked to carbon and waste valorization, when available in their jurisdiction.

For buyers evaluating supply partners, polymer form and conversion readiness are key. If your goal is to source industrial-grade material for conversion, explore PHA pellets and selection criteria aligned with processing needs and end-of-life requirements. For application development in additive manufacturing, PHA can also be positioned through PHA filament use cases where biodegradability and renewable sourcing can support differentiated products.

From business case to industrial reality: planning priorities for 2026

Engineering and pre-operative costs that reduce execution risk

Before first production, projects typically include feasibility studies, techno-economic analysis, strain selection or licensing, detailed engineering and plant layout, environmental impact assessment, regulatory approvals, equipment procurement and qualification, and commissioning with validation protocols. Hiring and training can be substantial because fermentation operations require experienced bioprocess operators, engineers, and QC staff. Early-stage budgeting should also include initial feedstock inventory and trial runs to stabilize yield and polymer quality before commercial ramp-up.

Operational excellence: the critical success factors to protect ROI

Plants that reach sustainable profitability usually prioritize three areas: secure feedstock supply, robust process control, and consistent product quality. Long-term sourcing contracts and flexible input options can reduce volatility. Advanced automation (DCS/SCADA), batch documentation, and laboratory information management can improve traceability and reproducibility. Finally, certifications for biodegradability and compostability and strong technical documentation can help unlock premium applications and long-term customer agreements.

If you are evaluating a PHA production project or need industrial-grade material for trials and scale-up, contact PHA Sourcing to discuss specifications, sourcing options, and conversion requirements aligned with your target application.