A Dual Solution to Global Waste Challenges

The interconnected problems of food waste and plastic pollution represent two of the most pressing environmental challenges of our time. Globally, approximately one-third of all food produced goes to waste, while plastic packaging continues to accumulate in landfills and oceans. Researchers at Binghamton University in New York State have developed an innovative solution that addresses both issues simultaneously by transforming food waste into biodegradable plastic.

The Research Breakthrough

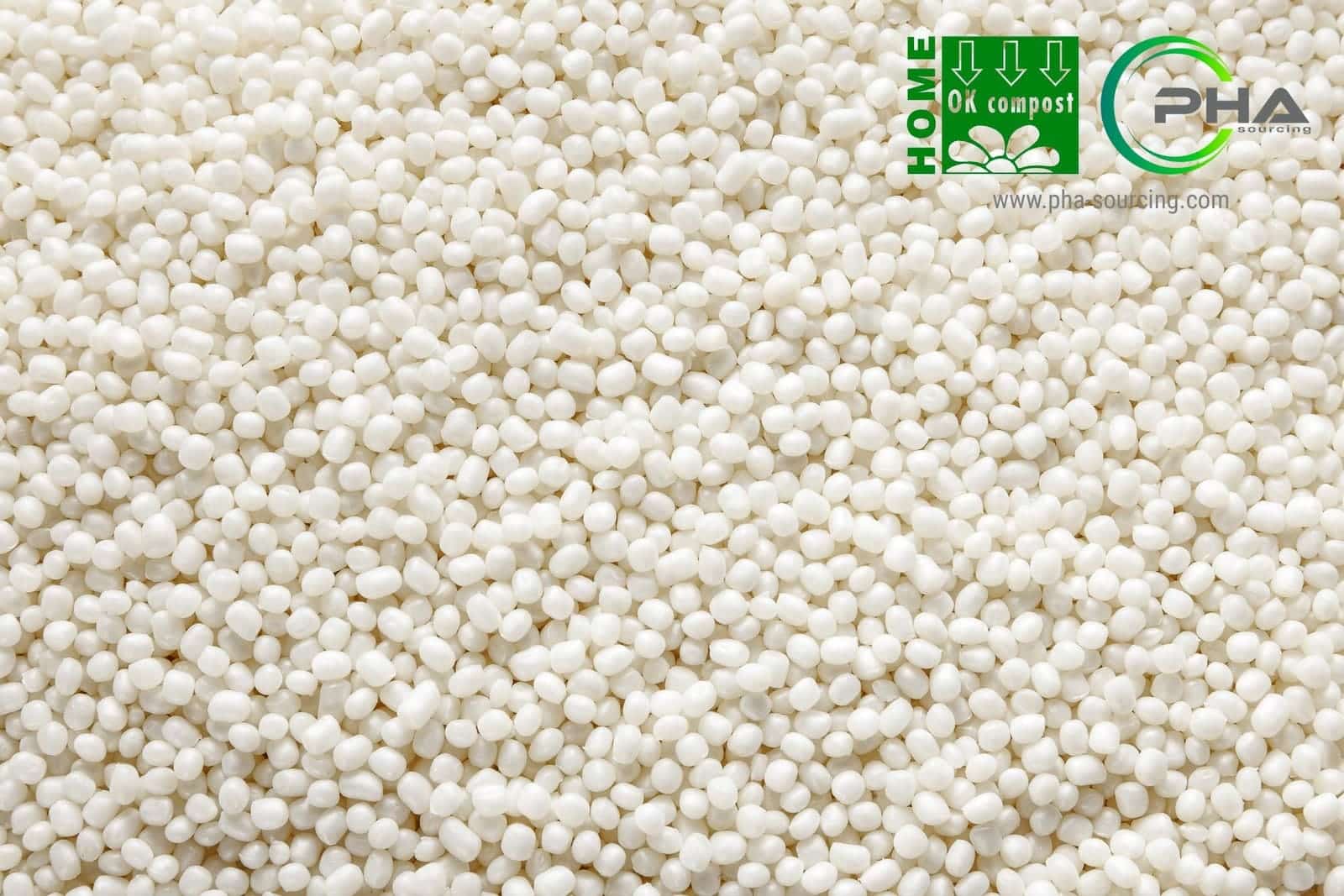

Professor Sha Jin and her team at Binghamton University have pioneered a process that converts food waste into polyhydroxyalkanoate (PHA) plastic, a fully biodegradable material with properties comparable to conventional plastics. The inspiration for this research came from observing the university’s dining hall waste management practices, where food waste was being sent to local farmers for livestock feed.

“We saw an opportunity to create even more value from this waste stream,” explained Professor Jin. “Our goal was to develop a process that could directly convert food waste into biodegradable plastics, which would be more valuable than using it solely for animal feed.”

The Conversion Process

The Binghamton team’s innovative approach involves several key steps. First, food waste undergoes lactic acid fermentation. This fermented product is then combined with ammonium sulfate and fed to Cupriavidus necator bacteria. These microorganisms naturally synthesize PHA as a means of storing carbon and energy. Remarkably, the process achieves approximately 90% PHA yield from the bacterial biomass, which can then be harvested and molded into various biodegradable products.

One of the most significant advantages of this process is its flexibility with food waste inputs. The research team discovered that the bioconversion process works effectively with mixed food waste types, as long as they are combined in consistent ratios. This flexibility is crucial for potential industrial-scale applications where waste streams would naturally contain diverse food types.

Key Advantages of the New Process

The Binghamton University method offers several compelling benefits over traditional biodegradable plastic production methods. Conventional PHA production typically relies on refined sugar substrates and pure microbial cultures, which can be expensive. In contrast, this new process utilizes readily available food waste as its primary input, significantly reducing production costs.

Additionally, the process demonstrates remarkable robustness in handling food waste. The research showed that food waste could be stored for up to a week without adversely affecting the bioconversion process. This storage capability provides essential flexibility for waste collection and processing at an industrial scale, making the technology more practical for real-world implementation.

Environmental and Economic Implications

The environmental benefits of this innovation are substantial. By diverting food waste from landfills, the process reduces methane emissions—a potent greenhouse gas produced when organic waste decomposes anaerobically. Simultaneously, it produces a biodegradable plastic alternative that can help reduce reliance on petroleum-based plastics, which contribute to long-term pollution and microplastic contamination.

From an economic perspective, the process creates value from what was previously considered waste. The resulting PHA plastic has commercial applications across various industries, including food packaging, beverage containers, and single-use items. This value creation could potentially make waste management more economically sustainable while providing businesses with genuinely eco-friendly packaging options.

Future Developments and Scaling Up

The research team at Binghamton University has ambitious plans to further develop and refine this process. One promising avenue of exploration involves utilizing the solid residue left over from the fermentation process as an organic fertilizer. This would create a closed-loop system where nearly all components of the food waste are converted into valuable products.

The next critical phase of this research involves scaling up the process to ensure it performs effectively at industrial levels. Successful scale-up would mark a significant milestone in making this technology commercially viable and accessible to waste management facilities and plastic manufacturers worldwide.

Scientific Validation and Findings

The study, led by Tianzheng Liu and published in Bioresource Technology, provides comprehensive scientific validation of the process. The research included detailed microbiota analysis, which revealed that lactic-acid-producing microorganisms dominate during the indigenous fermentation of food waste. This dominance is crucial for the consistent production of lactic acid, the key intermediate in the PHA production process.

Global transcriptomic and gene set enrichment analyses provided mechanistic insights into the process. The study found that coupling lactic acid with ammonium sulfate as carbon and nitrogen sources for PHA production using Cupriavidus necator bacteria enhances several metabolic pathways. These include PHA biosynthesis, CO2 fixation, carbon metabolism, pyruvate metabolism, and energy metabolism, all of which contribute to the high efficiency of the process.

The Promise of PHA in Sustainable Packaging

This research represents a significant advancement in the field of sustainable materials science. PHA plastics produced through this method offer a genuinely eco-friendly alternative to conventional plastics. Unlike some biodegradable plastics that require specific industrial composting conditions to break down, PHA can biodegrade in various environments, including marine settings, without leaving harmful residues.

The potential applications of this technology extend beyond simple waste reduction. By creating a circular economy for food waste and plastic production, this process could fundamentally transform how we approach both food waste management and plastic manufacturing. As the technology develops and scales, it may play a crucial role in helping industries meet sustainability goals and reduce their environmental impact.