Harnessing Australia’s Unique Microbiome for Plastic Alternatives

In a groundbreaking approach to combat plastic waste, Australian scientists are developing eco-friendly bioplastics using microbes sourced from the country’s unique environmental ecosystems. These innovative bioplastics are engineered to break down completely in various natural environments, including land, soil, and water, offering a promising solution to the global plastic waste crisis, particularly for single-use food packaging.

The Bioplastics Innovation Hub: A Collaborative Effort

At the forefront of this research is the Bioplastics Innovation Hub (BIH), a strategic partnership between Murdoch University and the Commonwealth Scientific and Industrial Research Organisation (CSIRO). This collaborative initiative brings together experts from diverse fields, including microbiology, genetics, and engineering, to develop plastics that can vanish without leaving harmful traces in the environment.

The Hub’s work is particularly focused on creating fully compostable food packaging solutions. This research is driven by the urgent need to address Australia’s packaging waste problem, where a 2021 study revealed that over 80% of food packaging ends up in landfills and cannot be recycled through standard household recycling programs.

Addressing the Challenges of Food Packaging

Professor Daniel Murphy, Director of the Bioplastics Innovation Hub, explains that one of the key challenges in food packaging is developing compostable linings for paper and cardboard containers. While some compostable packaging options exist for naturally protected foods like eggs and fruits, processed foods often require plastic linings to maintain safety and freshness standards.

“Our research aims to develop bioplastic linings that meet all industry safety standards while being fully compostable,” Professor Murphy states. “This would provide a sustainable alternative that appeals to both manufacturers and eco-conscious consumers who are increasingly demanding environmentally friendly packaging solutions.”

Utilizing Australia’s Native Microbes

A distinctive aspect of this research is the use of Western Australia’s native microbes. These locally sourced bacteria have unique properties that make them ideal for bioplastic production. They naturally store organic molecules that can be extracted and processed into bioplastics, leveraging Australia’s rich microbial diversity to create sustainable materials well-adapted to local environmental conditions.

This approach not only results in more sustainable packaging materials but also reduces the environmental impact of their production by utilizing locally available resources. By harnessing the unique characteristics of these native microbes, the research team is able to develop bioplastics that are both effective and environmentally friendly.

Government Support and National Priorities

The Australian government has shown strong support for this type of innovative research through its 10-year science plan, which emphasizes recycling and the development of a circular economy. The plan identifies addressing critical issues such as decarbonization and biodiversity loss as national priorities, with sustainable materials research playing a key role in achieving these goals.

The ultimate aim of the Bioplastics Innovation Hub is to develop bioplastics that can be used in every household, making sustainable packaging choices accessible to all Australians. This aligns with the government’s broader objectives of promoting sustainability and reducing plastic waste.

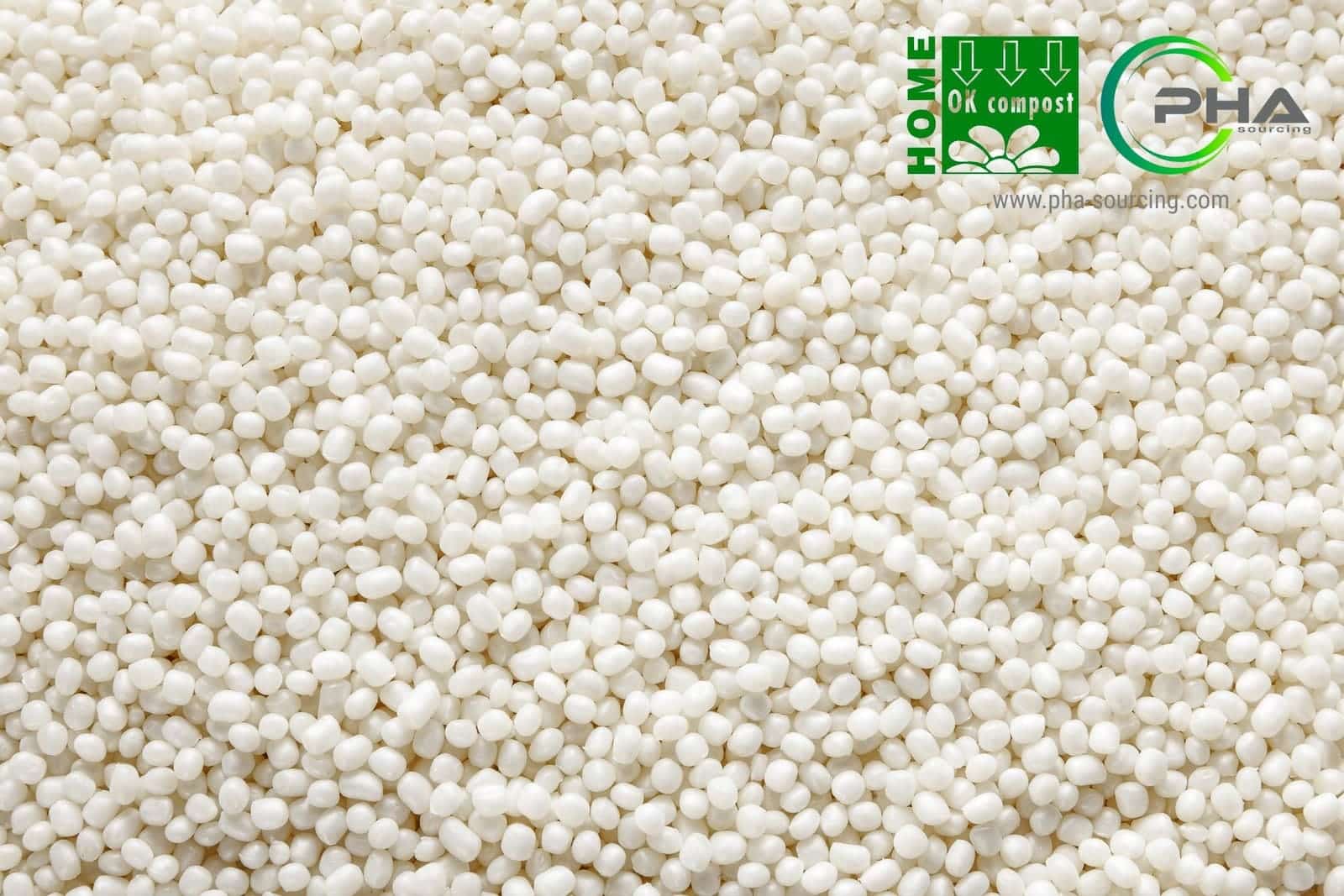

The Potential of PHA in This Context

While the Australian research focuses on various types of bioplastics, Polyhydroxyalkanoates (PHA) represent a particularly promising class of microbe-produced bioplastics that could complement these efforts. PHA materials share many of the desirable properties being developed in the Australian research, including complete biodegradability and compatibility with food packaging applications.

PHA offers several advantages that align well with the goals of the Bioplastics Innovation Hub. These include excellent barrier properties for food preservation, heat resistance for various packaging applications, and the ability to be processed using conventional plastic manufacturing equipment. Additionally, PHA’s versatility allows for its use in a wide range of packaging solutions, from food containers to flexible films and beverage capsules.

Environmental Benefits and Future Prospects

As global concerns about microplastics and plastic pollution continue to grow, this Australian research offers significant hope for cleaner land and water ecosystems. By developing bioplastics that can fully break down in natural environments, scientists are creating solutions that could help protect the planet for future generations.

The use of locally sourced microbes not only makes the production process more sustainable but also ensures that the resulting bioplastics are well-suited to Australia’s unique environmental conditions. This localized approach could serve as a model for other regions to develop their own sustainable packaging solutions using native resources.

Looking ahead, the successful development and commercialization of these microbe-based bioplastics could transform the packaging industry, offering truly sustainable alternatives to conventional plastics. As research continues and these materials become more widely available, they have the potential to significantly reduce plastic waste and contribute to a more circular economy.