PHA for Medical Technology

PHAs combine durability and functionality, making them suitable for medical devices. With the growing urgency to reduce plastic waste and the ecological footprint, PHA is more than just topical. A new era in medicine has begun.

PHA Sourcing supports medical technology

We help healthcare professionals make the transition to sustainable, high-performance materials. Our biodegradable PHA solutions are testament to your desire to innovate for the benefit of patients: medicine is constantly evolving. In limited series, or even at a large scale, our teams will support you in your transition. Let’s talk specifics.

Let’s take a look at how this bioplastic can be used to treat people.

Foreword: definition and properties of PHA

What is PHA?

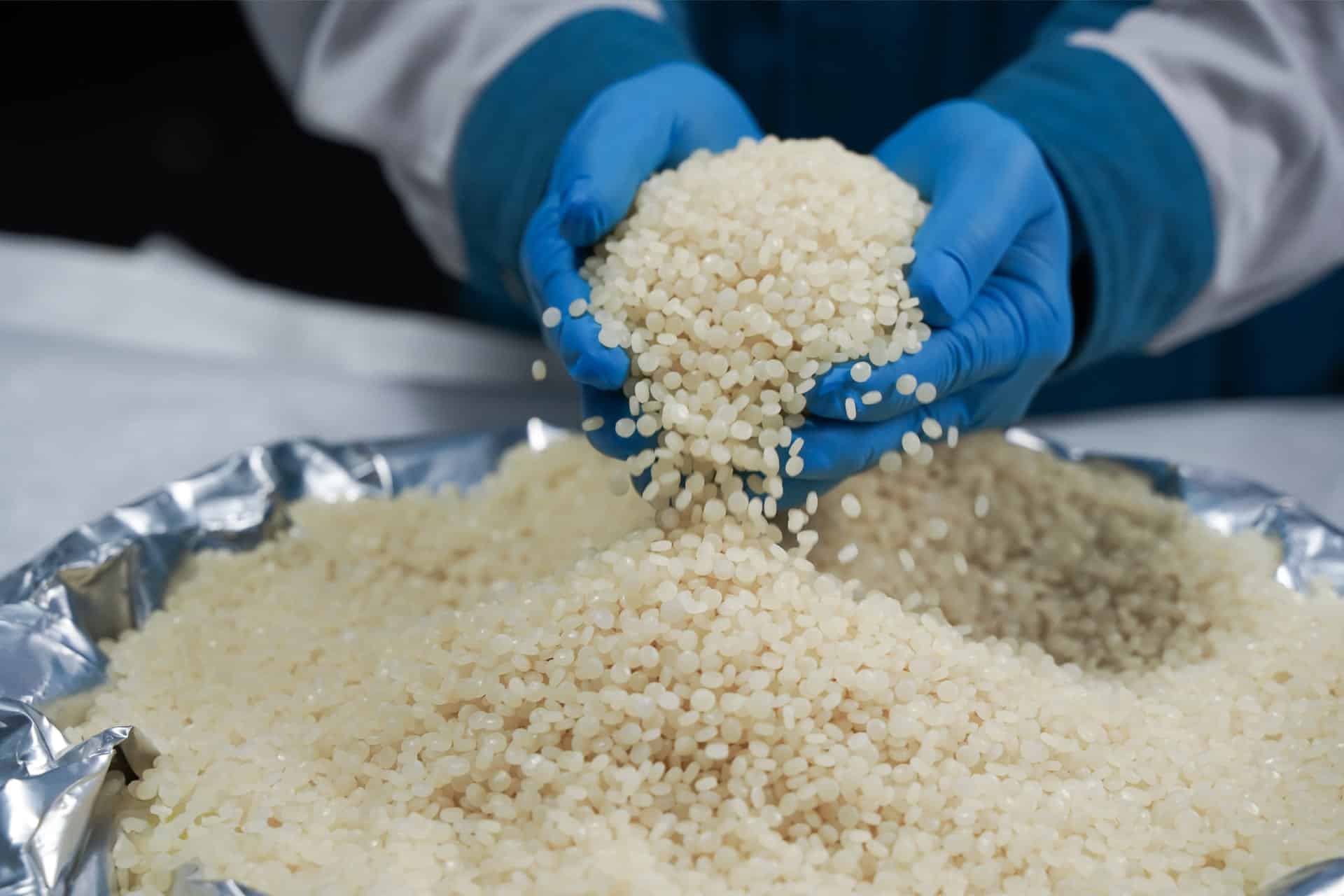

Polyhydroxyalkanoate is a biopolymer produced by certain bacteria. It is formed by fermenting renewable raw materials such as sugars or vegetable oils. This biological process creates a material that is 100% biodegradable, unlike traditional petroleum-based plastics.

Because of its biocompatibility and ability to decompose under natural conditions, PHA represents the future. An eco-responsible – and technologically viable – future for a variety of sectors, including medicine.

Organic Alternatives for Medicine: What are the Benefits of PHA?

PHA has a unique combination. Between its physical, chemical and mechanical properties, modified as required, it can be manufactured in a variety of forms. Films, fibres or even particles offer a wide range of uses that are ideal for medical technology.

For the body, it is (obviously) safe and provides additional advantages in medical environments:

- natural decomposition

- guaranteed hygiene

- no toxic residue

- high resistance to humidity

- proven durability

When plastics and medicine go hand in hand

Only 2 to 3% of the world’s plastic production is used in medical technology. On the other hand, over 50% of medico-pharmaceutical products are made from plastic. In addition to these polluting containers, which can be improved by the use of biopolymers, PHA has a wide range of applications. Let’s find out how it can be used in the healthcare sector.

Technology: the Medical Applications of PHA

Because of their biocompatibility and biodegradability, PHAs reduce the risk of inflammation while promoting effective integration with human tissue. They are therefore used to create implants, sutures, healing patches and tissue regeneration supports.

PHA implants and prostheses

Unlike plastic or metal implants, those made from PHA offer a biodegradable alternative. Once implanted in the body, these bioplastic products degrade gradually without leaving any toxic residue. This means that the implant does not have to be surgically removed. The advantage? The risks and costs associated with further operations are erased.

Medical technology: PHA for biodegradable sutures

Biodegradable PHA sutures are widely used to close surgical wounds. They decompose naturally in the body, avoiding the need for a second operation to remove them. These sutures even promote faster healing and reduce the risk of infection. PHA sutures are also just as strong as those made from synthetic polymers, but they offer one significant advantage; biodegradability.

Tissue regeneration supports

PHA is also used to design ‘scaffolding‘. Yes, the term may come as a surprise. In short, these medical supports ensure tissue regeneration. These temporary structures serve to guide cell growth before breaking down naturally. This process is particularly useful in regenerative medicine for bone or soft tissue. PHA supports are effective in supporting cell proliferation and tissue regeneration without toxic effects.

The Benefits of PHA in Medical Technology

Biocompatibility and tolerance of PHA

PHA is well tolerated by the human body, with few if any adverse reactions. This characteristic is essential for medical applications, since the materials used must interact with tissues without causing inflammation or rejection. PHA polymers are particularly effective in clinical settings because of their biocompatibility and biodegradability.

Proven durability and minimised environmental impact

PHA joins the family of biodegradable materials, since it breaks down into natural products (water and carbon dioxide). Unlike traditional plastics, which can take centuries to break down, PHA can degrade in a matter of weeks. In other words, using PHA considerably reduces the ecological footprint of medical devices.

Reducing medical waste

For medical technology, PHA could help reduce the amount of waste produced by the healthcare industry. Hospitals and clinics currently generate a staggering amount of non-recyclable plastic waste. But there are other ways for manufacturers to deal with this. With performance levels equivalent to – or even better than – those of conventional plastics, this biopolymer embodies the future of medical devices.

PHAs represent a breakthrough in the healthcare sector. Thanks to their biocompatibility and biodegradability, they offer a wide range of applications and support medical technology. These biopolymers offer innovative solutions for manufacturing devices, assisting tissue regeneration and delivering drugs.

Contact

Let’s Work Together on Your Next Sustainable Project

Ready to switch to PHA or explore how it can revolutionize your products? Contact us to discuss how we can support your sustainability goals with scalable PHA solutions.